From:https://vijaykarma.com/preferred-number-series-machine-design/

Preferred Series Numbers in Machine Design and Drawing

Table of Contents

What is Preferred Series Numbers?

The Preferred Series Number is a designed machine component that needs standardization to avoid variations. It implies that the product’s important parameters should be common in nature. For example, the sizes of the ingots (Raw Material) available in the market have standard sizes. A manufacturer does not produce ingots of sizes of his wish, he must follow a definite pattern to produce the ingots in that size. The designer can choose the dimensions from those standard available sizes.

Motor speed, the engine power of a tractor, machine tool speed and feed, all follow a definite pattern or series. This also helps in the interchangeability of products. It has been shown by experience that if the sizes are put in the form of geometric progression, then wide ranges are covered with a definite sequence.

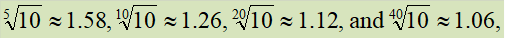

These numbers are called preferred series numbers having common ratios as,

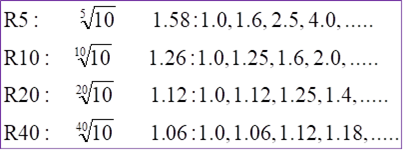

Depending on the common ratio, four basic series are formed; these are R5, R10, R20 and R40. These are named as Renard series (French balloonist and engineer Charles Renard). Many other derived series are formed by multiplying or dividing the basic series by 10, 100 etc. Typical values of the common ratio for the four basic Geometric Progression series are given below.

Examples of R5/R10/R20/R40 Number Series

- R10, R20 and R40: Thickness of sheet metals, wire diameter.

- R5, R10, R20: Speed, layout in a machine tool (R10: 1000,1250,1600, 2000)

- R20 or R40: Machine tool feed.

The hoisting capacities (in tonnes) of cranes are in R10 series, while the hydraulic cylinder diameters are in R40 series and hydraulic cylinder capacities are in R5 series. Wire diameter of helical springs are in R20 series.

Types of Preferred Series

There are two types of series Basic Number Series and Derived Number Series and derived series are further divided into Method 1 and Method 2.

Basic series of preferred numbers

“R5, R10, R20, R40 and R80 are called basic series.”

Any series that is formed based on these five basic series is called derived series.

Derived series of preferred numbers

There are two methods of forming derived series, namely, reducing the numbers of a particular basic series or increasing the numbers.

Methods of Forming Derived Series(Derived Series in Machine Design)

Method 1

In the first method, a derived series is obtained by taking every second, third, fourth or pth term of a given basic series. Such a derived series is designated by the symbol of the basic series followed by the number 2, 3, 4 or p and separated by ‘/’ sign.

If the series is limited, the designation also includes the limits inside the bracket. If the series is unlimited, at least one of the numbers of that series is mentioned inside the bracket.

Let us consider the meaning of these designations.

(i) Series R 10/3 (1, …,1000) indicates a derived series comprising of every third term of the R10 series and having the lower limit as 1 and a higher limit as 1000.

(ii) Series R 20/4 (…, 8, …) indicates a derived series comprising of every fourth term of the R20 series, unlimited in both sides and having the number 8 inside the series.

(iii) Series R 20/3 (200, …) indicates a derived series comprising of every third term of the R20 series and having the lower limit as 200 and without any higher limit.

(iv) Series R 20/3 (…200) indicates a derived series comprising of every third term of the R20 series and having the higher limit as 200 and without any lower limit.

Read more topics and video tutorials on Machine Design & Drawing

Method 2

In the second method, the derived series is obtained by increasing the numbers of a particular basic series. Let us consider an example of a derived series of numbers ranging from 1 to 1000 based on the R5 series.

- The numbers belonging to the R5 series from 1 to 10 are as follows: 1, 1.6, 2.5, 4, 6.3, 10

- The next numbers are obtained by multiplying the above numbers by 10 are as follows: 16, 25, 40, 63, 100

- The same procedure is repeated, and the next numbers are obtained by multiplying the above numbers by 10 are 160, 250, 400, 630, 1000

Therefore, the complete derived series based on R5 series is as follows: 1, 1.6, 2.5, 4, 6.3, 10, 16, 25, 40, 63, 100, 160, 150, 400, 630, 1000

The advantage of derived series is that one can obtain geometric series for any range of numbers, that is, with any value of the first and the last numbers. Also, one can have any intermediate numbers between these two limits.

References

- ABDULLA SHARIF, Design of Machine Elements, Dhanpat Rai Publications (P) Ltd, New Delhi, 1995

- V. B. Bhandari, Design of Machine Elements, Third Ed., The McGraw-Hills Companies, New Delhi

- R. S. KHURMI and J.K. GUPTA, A Text-Book of Machine Design, S.Chand and company ltd., New Delhi, 2000. Design of Machine Elements https://nptel.ac.in/courses/112/105/112105125/

Q & A

- Find out the numbers of the R5 basic series from 1 to 25.

- Find out the numbers of R20/4 (100, . . . . . . . . . . , 1000)derived series.

- A manufacturer is interested in starting a business with five different models of tractors ranging from 7.5 to 75 kW capacities. Specify the power capacities of the models. There is an expansion plan to further increase the number of models from five to nine to fulfil the requirement of farmers. Specify the power capacities of the additional models.

- It is required to standardize eleven shafts from 100 to 1000 mm diameter. Specify their diameters.

From:http://www.zjkju.edu.cn/machine/info/1049/3371.htm

你可知道粗糙度为什么是0.8, 1.6, 3.2, 6.3, 12.5?

你可知道油缸缸径为什么是63, 80, 100, 125?

你可知道油缸压力为什么是6.3, 16, 25, 31.5?

你可知道螺纹规格为什么是6, 8, 10, 12, 14, 16?

你可知道机械设计手册上无数的表格,所有产品样本上的参数表,都是怎么来的?

一切都来源于伟大的优先数系!

法国工程师雷诺看到热气球上的钢丝绳规格繁多,他就想了一个办法,将10开5次方,得到一个数1.6,然后辗转相乘,得出5个优先数如下:

1.0

1.6

2.5

4.0

6.3

这是一个等比数列,后数为前数的1.6倍,那么10以下的钢丝绳一下子只有5种,10到100的钢丝绳也只有5种,即10, 16, 25, 40, 63

但是这样分法太稀疏,雷先生就再接再厉,将10开10次方,得出R10优先数系如下:

1.0

1.25

1.6

2.0

2.5

3.15

4.0

5.0

6.3

8.0

公比为1.25,于是10以内的钢丝绳只有10种,10到100的也只有10种,这就比较合理了。这时肯定有人说,这个数列,前面的数字好像相差不大,如1.0和1.25,简直没差别嘛,平常我就四舍五入了,但6.3和8.0间隔就大了,这样合理吗?

合理不合理,我们打个比方。比如说自然数1、2、3、4、5、6、7、8、9,看起来很顺溜,我们用这个数列来发工资,给张三发1000,给李四发2000,两人皆心服。突然通货膨胀,给张三发8000,给李四发9000。以前李四工资是张三的2倍,现在变成1.12倍。你说李四能愿意吗?他可是主管哪,给他发16000还差不多,张三是不会埋怨说主管比他多8000的。

这个自然界的事物,有两种比较方法,就是“相对”与“绝对”!优先数系是相对的。

有人说他的产品规格有10吨,20吨,30吨,40吨的,现在看来就不合理了吧?如果你取两倍的话,应该是10吨,20吨,40吨,80吨,或者保住头尾,也应该是10吨,16吨,25吨,40吨,公比为1.6才合理。

这就是“标准化”,论坛上常常看到有人说“标准化”,实际他们说的是“标准件”,所做的工作只是将整机的标准件整理一下,就叫标准化了,实际不是这样的。真正的标准化,你要把你的产品的所有参数按优先数系形成序列化,再把所有的零部件的功能参数及尺寸,用优先数系来序列化才对。

自然数是无穷的,但在机械设计师眼里,世界上只有10个数,它就是R10优先数。并且,这10个数相乘,相除,乘方,开方,结果还在这10个数里,何其奇妙!当你设计的时候,不知道尺寸该选择多大为好时,就在这10个数里选,你说何其方便!

1.0 N0

1.12 N2

1.25 N4

1.4 N6

1.6 N8

1.8 N10

2.0 N12

2.24 N14

2.5 N16

2.8 N18

3.15 N20

3.55 N22

4.0 N24

4.5 N26

5.0 N28

5.6 N30

6.3 N32

7.1 N34

8.0 N36

9.0 N38

两个优先数,比如4和2,其序号分别为N24和N12,它们相乘,将其序号相加,其结果等于N36即8便是;相除,序号相减,等于N12即2便是;2的立方,将其序号N12乘以3得N36即8便是;4的开方,将其序号N24除以2得N12即2便是如果求2的四次方呢?N12*4=N48,这里没有,怎么办?上面的列表,没有写上一个数,就是10,它的序号是N40,凡是序号大于40的,只看大于40的部分,比如N48就看N8,即1.6,然后乘以10得16就对了。请关注我们的微信号:auto1950 。如果序号是N88呢,看N8得1.6,然后乘以100得160便是,因为100的序号是N80,1000的序号是N120,依此类推做机械设计,一辈子用这20个数就足矣。但有时需用到R40数系,有40个数,就更完善了,若不够,还有R80系。我已将R40数系倒背如流,应付一般计算根本不用计算器。简单来说算40径的45钢的抗扭能力,其扭转系数是0.5*π*R^3,扭应力选屈服点360的一半即180MPa,圆周率选3.15,左右手捏小数点,心算加减序号,一会就出来。有人说你不加安全系数吗?说吧,是取1.25,还是1.5,还是2啊?呵呵。

黄金分割0.618,也即1.618,这里也有1.6。

平方根数列,就是根号1,根号2,根号3,很容易求出吧?(3的序号是N19)

π的平方等于多少?等于10。你算压杆稳定的时候就方便了吧?

圆杆扭转系数约为0.1*D^3,现在你可以口算扭转系数了吧?

为什么大螺丝从M36直接跳到M40?

为什么齿轮的传动比有个6.3或者7.1?

为什么槽钢有个市场上很少见的12.6号?

为什么外协厂打电话来说140的方管没有,而有120和160的?因为R5数系比R20数系优先。

为什么标准件的参数有个第一序列,第二序列?一般来说第一序列就是R5序列。

为什么Inventor的螺孔列表有个M11.2?现在你知道它不是胡诌出来的数吧?

还有钢板厚度,型钢型号,齿轮模数,一切标准件,一切工业品样本上的功能参数,尺寸参数,标准公差表,等等等等,它们的来源,此刻在我们的心中慢慢清晰起来。可以说,我们已经理解了半部机械设计手册,以及那些还没做出来的工业品。

那么,我们在设计产品的时候,就可以同时设计出一系列了,而不是设计完之后再进行所谓的“标准化”;更进一步,如果产品注定要序列化,那么我们甚至可以在对实际工况不甚了解的情况下设计产品,因为优先数系已将所有型号包括其中了。

优先数系的应用,上面列出的,可谓沧海一粟,无尽的应用等着我们自己去开发。

1、粗糙度的概念

零件经过加工后,由于刀具、积屑瘤和鳞刺等给工件表面造成或大或小的波峰与波谷。这些峰谷的高低程度很小,通常只有放大才能看见。这种微观几何形状特征,称为表面粗糙度。

2、粗糙度的评定参数

以Ra\Rz\Ry三种代号加数字来表示,机械图纸中都会有相应的表面质量要求,一般是工件表面粗糙度Ra<0.8um的表面时称作:镜面。

轮廓算术平均偏差Ra:在取样长度L内轮廓偏距绝对值的算术平均值

微观不平度十点高度Rz:在取样长度l内5个最大的轮廓峰高的平均值与 5个最大的轮廓谷深的平均值之和

轮廓最大高度Ry:在取样长度L内轮廓峰顶线与轮廓谷底线之间的距离

3、粗糙度的测量和标注

用电子仪器或光学仪器测量出Ra、Rz和Ry的数值即可定量评定表面粗糙度。在实际生产中,经常凭人的视觉和触感并用样块与被加工表面相比较来鉴定其粗糙度。

标注方法:在零件图上用符号标注加工表面的特征。为基本符号,单独使用这一符号是没有意义的,加注参数值时表示表面可用任何方法获得。

4、各种机械加工工艺获得粗糙度等级

关于表面粗糙度的数值和表面特征、获得方法、应用举例请参见下表

留言列表

留言列表